close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

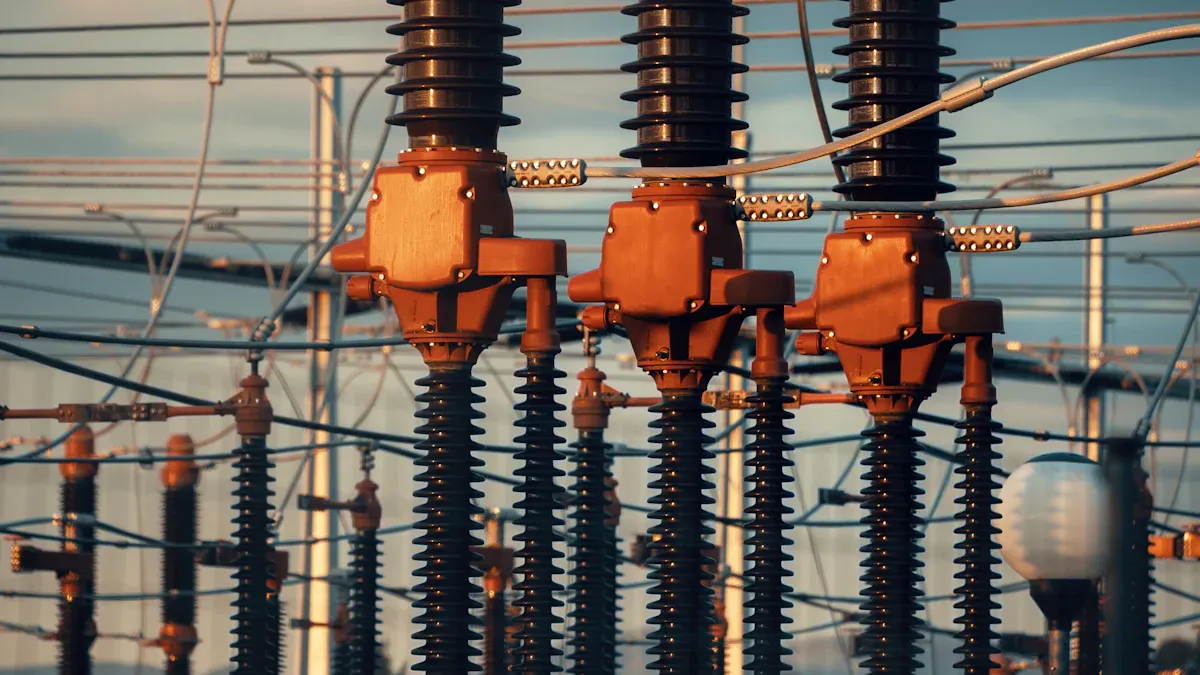

You can answer the question, what is an oil-immersed current transformer?, by looking at how it measures electrical current while staying submerged in insulating oil. This transformer works in power systems where you need high reliability. The oil cools the device and keeps electrical parts safe from damage.

Oil-immersed current transformer designs often last longer and handle high voltages better than dry-type models.

Oil-immersed current transformers use insulating oil to cool and protect electrical parts, ensuring safe operation in high-voltage environments.

These transformers last longer than dry-type models due to their effective insulation and cooling, making them a cost-effective choice for power systems.

Regular maintenance, including oil quality checks, is crucial to prevent overheating and ensure the transformer operates efficiently.

Advanced materials and smart technology in modern designs enhance energy efficiency and allow for real-time monitoring of transformer conditions.

Oil-immersed transformers are ideal for outdoor installations, as they withstand harsh conditions and provide reliable performance.

You may wonder, what is an oil-immersed current transformer? This device measures electrical current in high-voltage power systems. You find it filled with insulating oil, which protects the internal parts and helps control temperature. The oil-immersed current transformer plays a key role in monitoring and protecting electrical networks. You use it to step down large currents so that meters and relays can safely measure and respond to changes.

Today, oil-immersed current transformer designs use advanced materials and smart technology. Engineers have introduced amorphous alloy cores, which improve energy efficiency and reduce losses. You also see nanocrystalline alloys that lower core losses and boost magnetic performance. Many modern transformers now include IoT-enabled monitoring systems. These allow you to check the condition of your transformer in real time and predict maintenance needs. This technology supports smart grids and renewable energy systems.

When you look inside an oil-immersed transformer, you find several important parts:

Core: This part guides the magnetic field and helps transfer energy. Newer cores use special alloys to reduce energy loss.

Windings: You see coils of wire wrapped around the core. These carry the electrical current and create the magnetic field.

Insulating oil: This liquid surrounds the core and windings. It keeps the transformer cool and prevents electrical breakdown. Insulating oil also protects against moisture and dirt.

Tank: The outer shell holds the insulating oil and keeps everything sealed.

Bushings: These allow wires to enter and exit the tank without letting oil leak out.

Monitoring devices: Many oil-immersed current transformer models now include sensors and smart systems. You can track temperature, oil quality, and electrical performance.

Tip: Regularly check the quality of the insulating oil. Clean oil helps your transformer last longer and work safely.

You must make sure your oil-immersed current transformer meets industry standards. The table below shows the main certifications you should look for:

Standard Type | Description |

|---|---|

ANSI/IEEE | Ensures safety, reliability, and interoperability required by utilities and electrical codes. |

IEC | International standards for electrical equipment, including transformers. |

UL Certification | Available for additional safety assurance. |

You rely on these standards to guarantee safe operation and long-term reliability. When you choose an oil-immersed current transformer, you get a device that combines strong insulation, efficient cooling, and advanced monitoring. This makes it a trusted choice for demanding electrical environments.

You see an oil-immersed current transformer in many power stations and substations. This device measures high electrical currents and steps them down to safer levels. You use it to protect equipment and monitor power flow. The transformer works by using magnetic induction. When current flows through the primary winding, it creates a magnetic field in the core. The secondary winding picks up this field and produces a smaller, proportional current. You connect this output to meters or relays for accurate readings.

The oil-immersed transformer uses insulating oil to keep the core and windings cool. You rely on this oil to prevent overheating during heavy electrical loads. The oil also stops electrical arcs and breakdowns. You find that the transformer can handle outdoor conditions, including high voltages and temperature changes. This makes it a reliable choice for demanding environments.

You may ask, what is an oil-immersed current transformer? The answer centers on the role of insulating oil. This oil provides two main benefits: insulation and cooling. You depend on the oil to separate live electrical parts and prevent short circuits. The oil also absorbs heat from the core and windings, keeping the transformer safe and efficient. You see this as especially important in outdoor settings, where temperature and humidity can change quickly.

You can choose between mineral oil and silicone-based oil for your transformer. Mineral oil is common because it has high dielectric strength and good thermal properties. Silicone-based oil resists fire and lasts longer, but costs more. Both types of insulating oil help your transformer work safely and efficiently.

Note: Insulating oil is crucial for reliable operation. You should check oil quality regularly to avoid problems.

You must consider the environment when you use an oil-immersed current transformer. Here are some important factors:

High humidity in tropical climates can let moisture enter the transformer. This reduces the dielectric strength of insulation materials.

Moisture causes the insulating oil to break down. You may see more acids and sludge, which lower the oil's insulating properties.

Salt-laden air in coastal areas speeds up corrosion of metal parts. This can reduce electrical reliability and safety.

You can compare mineral and silicone-based oils using the table below:

Oil Type | Dielectric Strength | Thermal Properties | Fire Resistance | Cost |

|---|---|---|---|---|

Mineral Oil | High | Good | Low | Lower |

Silicone-Based | Very High | Excellent | High | Higher |

You need to select the right oil for your application. This helps your transformer last longer and work safely.

You find oil-immersed current transformers in many places where reliable measurement and protection matter. These devices work best in environments that demand high voltage and stable performance. You see them in industrial plants, utility substations, and energy optimization projects. The robust design and use of insulating oil help these transformers handle tough conditions, such as outdoor installations and areas with high electrical loads.

Here is a table showing common applications and their benefits:

Application Type | Benefits |

|---|---|

Industrial Plants | High efficiency, low operational costs, and reduced noise levels. |

Utility Services | Robust construction, short-circuit resistance, and compliance with standards. |

Energy Optimization | Enhanced sustainability and reduced power loss. |

You rely on oil-immersed current transformers when you need accurate current measurement and long-term reliability. The insulating oil keeps the transformer cool and safe, even during heavy use. You also benefit from lower noise levels, which makes these transformers suitable for places where quiet operation is important.

You may wonder what is an oil-immersed current transformer? The answer becomes clear when you compare it to dry-type models. Oil-immersed transformers offer several advantages that make them a preferred choice for many applications.

Here is a table that highlights the main benefits:

Advantage | Description |

|---|---|

Excellent Insulation Performance | Transformer oil provides a highly reliable insulating environment, enabling these transformers to handle high-voltage, high-capacity scenarios. |

High Cooling Efficiency | The circulatory cooling capability of oil gives oil-immersed transformers better overload capacity and longer lifespan compared to dry-type transformers. |

High Cost-Effectiveness | For large power transformers, the oil-immersed design offers greater economic efficiency in terms of manufacturing and material costs. |

Mature and Reliable Technology | With over a century of development, the design, manufacturing, operation, and maintenance experience is vast, ensuring operational reliability. |

Lower Noise Level | The oil dampens vibrations from the core and windings, resulting in relatively lower operating noise. |

You notice that oil-immersed current transformers last longer than dry-type models. With proper care, dry-type transformers can last 20-30 years or more. Oil-immersed designs often exceed this lifespan because the insulating oil protects internal parts from heat and moisture. You also save money over time, especially with large transformers, since oil-immersed models have lower initial costs and better economic efficiency.

Tip: Choose an oil-immersed transformer for high-voltage, high-capacity projects. The insulating oil ensures safe operation and long-term durability.

You see that oil-immersed current transformers combine strong insulation, efficient cooling, and proven technology. These features make them a trusted solution for demanding electrical environments.

You need to follow a regular maintenance schedule to keep your oil-immersed current transformer working safely and efficiently. Routine checks help you spot problems early and prevent costly failures. Here are the recommended steps:

Monitor the oil temperature. Make sure it does not go above 95℃. Try to keep it below 85℃ during normal operation.

Listen for abnormal sounds. If you hear strange noises or see the oil temperature rising steadily, shut down the transformer for inspection.

Check the oil level every day. Low oil can expose the windings and core, leading to overheating.

Inspect all joints for signs of overheating. Hot spots may signal loose connections or electrical faults.

Test the insulating oil regularly. Clean oil keeps the transformer safe and maintains high dielectric strength.

Tip: A preventive maintenance schedule helps you extend the life of your oil-immersed current transformer and reduces downtime.

You can prevent most failures by following these steps. The table below shows common causes of failure and how you can avoid them:

Cause of Failure | Description | Preventive Measure |

|---|---|---|

Overheating | High temperatures damage insulation. | Ensure proper cooling and ventilation. |

Oil Contamination | Dirty oil lowers dielectric strength. | Test and replace insulating oil often. |

Oil Leakage | Leaks reduce insulation and cooling. | Inspect seals and gaskets regularly. |

Insulation Degradation | Moisture and heat weaken insulation. | Test insulation and keep oil clean. |

You must follow strict safety protocols when maintaining your transformer. These steps protect you and your equipment:

Isolate the transformer from the power supply before starting any work.

Use lockout-tagout devices to keep the transformer de-energized.

Inspect for leaks, especially around gaskets, valves, and connections.

If you suspect a leak but cannot see it, perform a pressure test.

Only qualified personnel should handle repairs, especially welding or structural fixes.

Use high-quality insulating oil that matches manufacturer specifications when refilling.

Filter the oil before adding it to remove dirt and moisture.

Watch the oil level closely to avoid overfilling.

Note: Oil immersion provides strong insulation, efficient cooling, and protection from moisture and oxygen. These features help your oil-immersed current transformer last longer and work reliably.

You can avoid most problems by following these safety steps and keeping your insulating oil clean. Oil immersion slows down insulation aging and keeps your transformer running smoothly for years.

You now understand that oil-immersed current transformers stand out for three key reasons:

The oil cools the transformer, preventing overheating.

The oil insulates electrical parts, stopping short circuits.

The oil boosts mechanical strength, protecting against stress.

Property | Typical Range | Importance |

|---|---|---|

Dielectric Strength | 30-50 kV/mm | Prevents electrical breakdown |

Viscosity | 8-12 cSt at 40°C | Improves cooling efficiency |

Flash Point | >140°C | Lowers fire risk |

Tip: Regular maintenance and oil checks help you keep your transformer safe and efficient for years.

You find oil-immersed transformers use insulating oil for cooling and protection. Dry-type transformers use air instead. Oil-immersed models handle higher voltages and last longer. Dry-type units work best indoors or in clean environments.

You should check the oil level and quality every three to six months. Regular checks help you spot leaks, contamination, or aging. Clean oil keeps your transformer safe and efficient.

Yes, you can install oil-immersed current transformers outdoors. The oil protects against moisture, dirt, and temperature changes. You must ensure the tank stays sealed and the oil remains clean for reliable operation.

Contaminated oil loses its insulating power. You may see overheating, short circuits, or even transformer failure.

Tip: Replace or filter the oil right away if you notice contamination.